Today, renewable resources are recycled with economic development models that are constantly looping and are becoming a global trend. The strategy of sustainable development is unanimously consent. Sustainable development is that it is in line with the needs of contemporary humans, and it is not harmed the development of future generations to meet its needs. It is our quantity of economic growth and pay attention to the quality of economic growth.

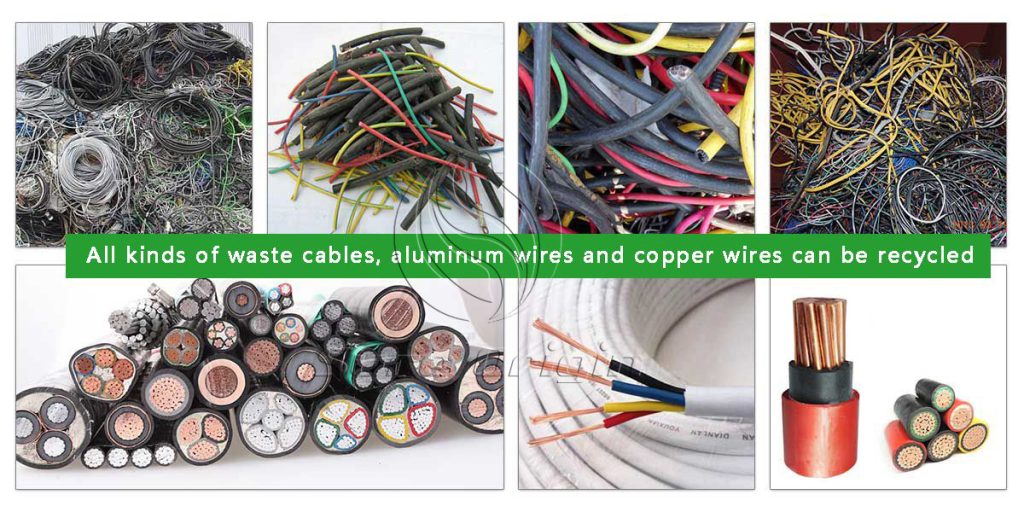

The main mark is that resources can be used forever, maintain a good ecological environment. With the development of social economy, the increase in people's living standards, the number of various industrial cables in waste cables has also increased sharply. At this time, it is very important to reasonably use the cable wire recycling regenerative resources.

The method currently dealing with the recycling of waste cables has the following:

(1) Incineration method: This method is to combust the waste wire cable with the properties of the cable skin, and then recover the copper inside. However, the drawback of this method is that during the process of wire incineration, the surface of the copper wire is severely oxidized, and the recovery of non-ferrous metals is reduced, and the combustion line skin has a large contamination of the environment, which is not conducive to sustainable development strategy. Not conducive to the construction and development of the global environment.

(2) Manual peeling method: This method uses artificial way to peel off the wire and cable, its work efficiency is high, and for some cable, the square line is also handled, if it is some car lines, network cable, home appliance demolition Solving the filament thread, the extraction of the metal is large, and the separation is not clean. In today's society, artificial cost is also a small expense. So this method is gradually eliminated.

(3) Mechanical peeling method: Treatment cable using cable peeling machine, but the law still requires manual operation, belonging to the semi-mechanization, high labor intensity, low efficiency, and is relatively high.

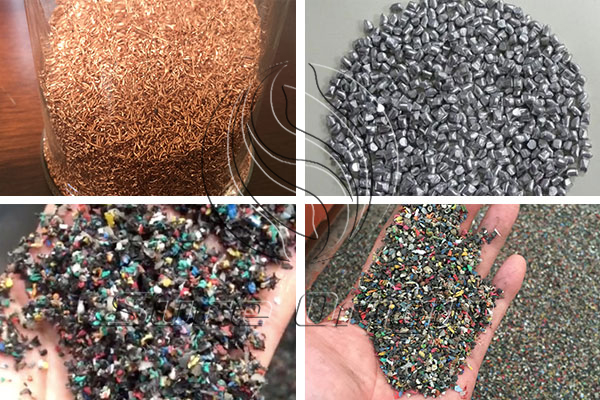

(4) Aluminum and Copper wire recycling machine: The mechanical pulverization method refers to the method of treating the use of copper meters. The copper wire crusher of Sure Group uses dry physical separation technology, first separated by crusher, extracting metal and non-metallic The metal recovery rate can reach 99%, and the operation method is also very simple. It only needs to put the waste cable into the copper crusher. After the processing of the device, pure copper rice and plastic can be obtained, and the separated pass can be directly For metal processing plants, processing metal items; plastics can also be sold directly to plastic processing plants, use as wood to add materials to achieve resource cycling. This method saves time and effort, the efficiency is low, and it is currently the primary choice for the recycling of waste cables now.

English

English