Machine Function:

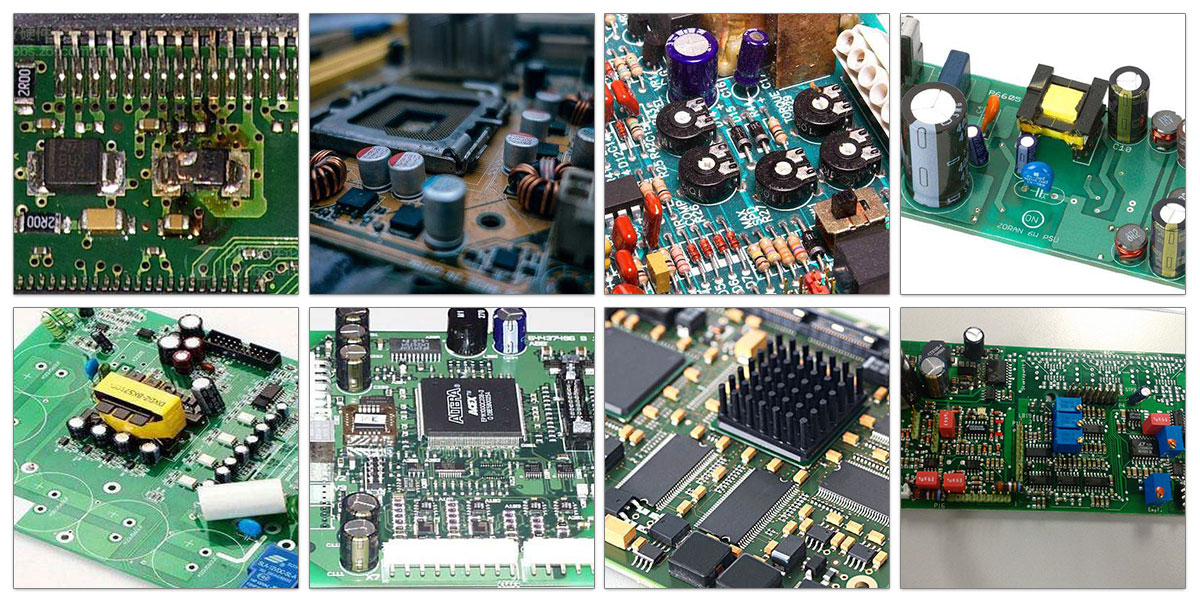

Waste circuit board electronic component dismantling machine is used to dismantle the electronic components from waste circuit boards, CCL,waste computer mother boards, waste cell phone motherboards, waste TV boards and PCB scrap etc.

Waste circuit board electronic component dismantling machine is low investment high profit project, environmental friendly project.

All kinds of waste circuit boards, CCL, waste computer mother boards, waste cell phone motherboards, waste TV boards, PCB scrap, copper-clad laminate, and other household appliances.

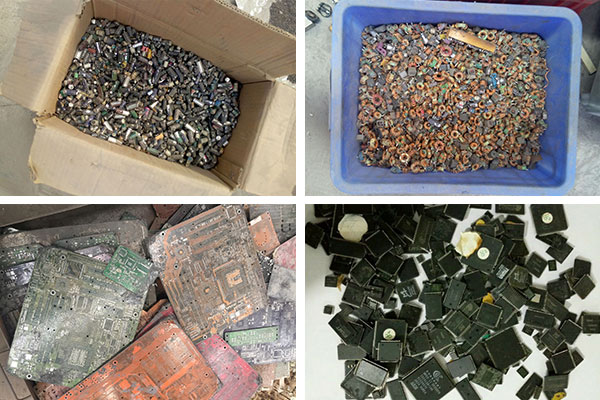

The final products of Waste circuit board electronic component dismantling machine is electronic components include Tin slags,IC chips,Capacitors,CPU/RAM etc.

1. Environmental friendly, all of the process with waste gas purification system.

2. High efficient, to remove tin and components from the same process.

3. Easy operation and less land occupation.

4.Advanced and automatic Design,automatic temperature control for heating device and automatic set for keeping operation temperature.

| Model | Range of temperature (℃) | Speed (r/min) | Power (kw) | External dimension (mm) | Weight (kg) |

| SY-C-80-90 | 25-300 | 5-60 | 3.75 | 1680*980*1420 | 585 |

| SY-C-90-110 | 25-300 | 5-60 | 4.75 | 1880*1080*1580 | 870 |

NOTE:

1. The above machine are our standard specification, for turnkey project, or for different raw materials machine solutions, please contact us about your raw materials;

2. The machine voltage can be customized.