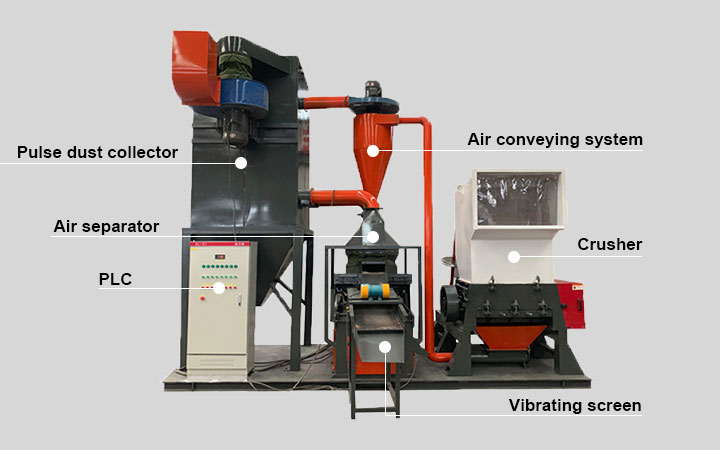

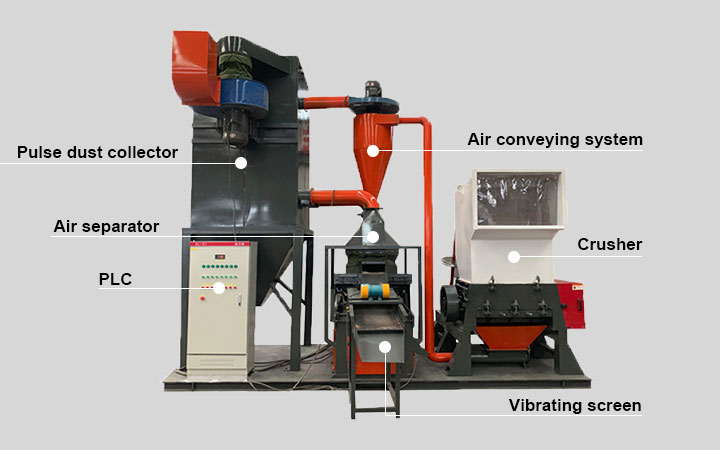

Machine Function:

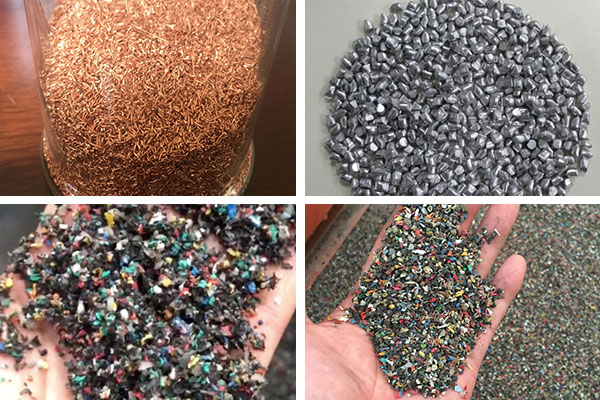

Aluminum and Copper wire recycling machine is used to recycle copper cable scrap and aluminum cable scraps and copper wires to get pure copper particles and plastic particles.

Aluminum and Copper wire recycling machine is low investment high profit project, environmental friendly project.

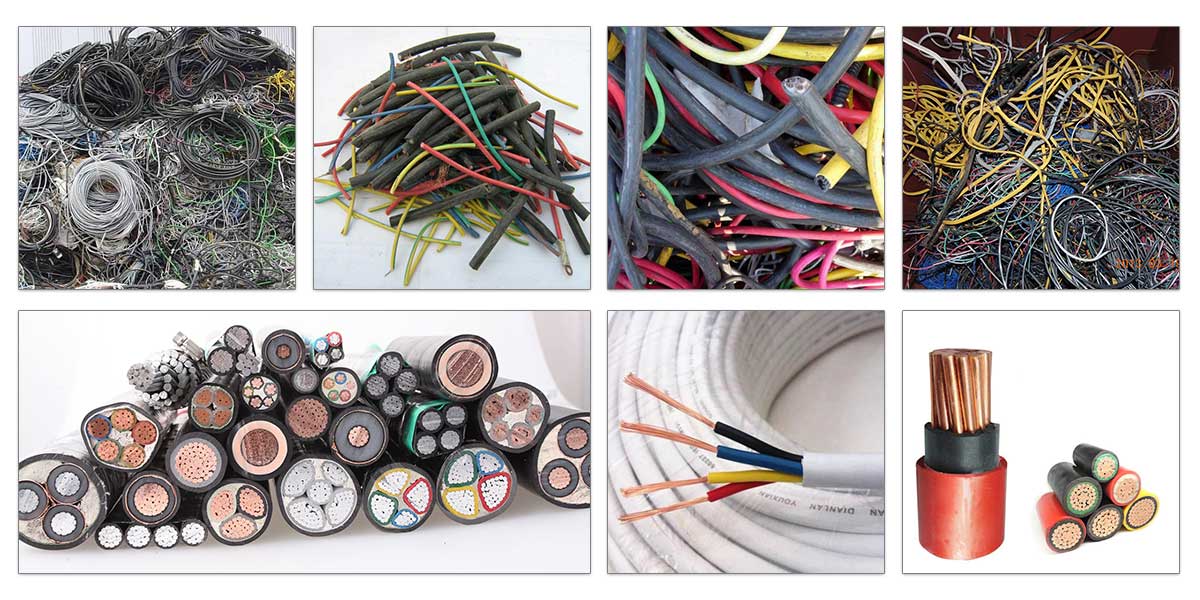

All kinds of waste copper wire,copper cable scrap and aluminum cable scraps and copper wires, automobile electrical wire ,car wire, motorcycle electric wire, computer wire and communication cables etc with diameter from 0.3mm to 20mm.

The final product Aluminum and Copper wire recycling machine is copper particles or aluminum particle and plastics particles.

1. One piece design, Integrated structure design, small occupied area, easy to move and operate.

2. Advanced PLC control system, only one operator for production.

3. Water cooling system in crusher to avoid over heat to prolong production time.

4. Good quality of SKD-11 alloy blades, the processing hardness is HR58.

5. Environmental-friendly operation . the advanced pulse dust removal system effectively collects dust in the production process.

6. 99 % high purity,by our high voltage electrostatic separator device , we can guarantee 99% copper recovery from the whole production to enlarge the commercial value for our clients.

| Model | Capacity (kg/h) | Power (kw) | Weight (kg) | External dimension (mm) |

| SY-C-400 | 100-150 | 18.7 | 1800 | 2000*1850*2600 |

| SY-C-600 | 300-400 | 45 | 3500 | 4200*1900*3800 |

| SY-C-800 | 500-600 | 45 | 4000 | 4500*2000*4000 |

| SY-C-1000 | 800-1000 | 65 | 4600 | 5180*2100*4200 |

NOTE:

1. The above machine are our standard specification, for turnkey project, or for different raw materials machine solutions, please contact us about your raw materials;

2. The machine voltage can be customized.