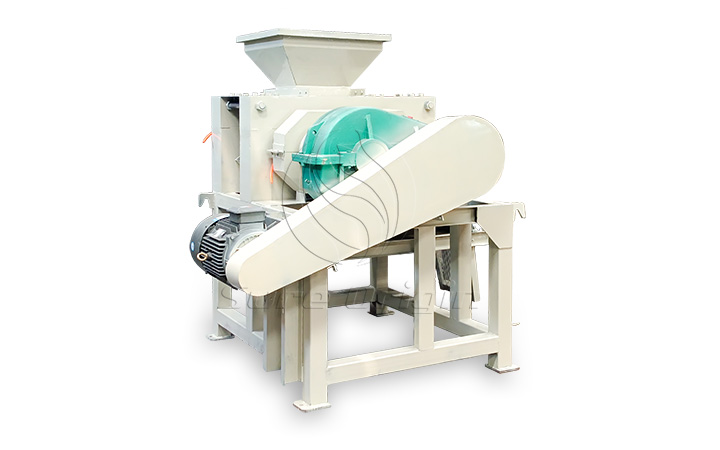

Briquette machine overview:

Briquette machine can mold a variety of mineral powder, metal powder, coal powder, coke powder and other materials by pressing. It is characterized by high briquetting pressure, adjustable revolutions, and a screw feeding device is alternative. The finished products can be used in different fields, such as coal, boilers, power plants, etc. charcoal briquettes can be used for barbecue.

Capacity:1-35 t/h

Power:5.5-90 kw

Briquette size:10-80 mm

Material: All kinds of material

Capacity:0.5-7 t/h

Power:18.5-90 kw

Briquette size:10-80 mm

Material: All kinds of material

Capacity:0.3-3.5 t/h

Power:15-18.5 kw

Briquette size:20mm to 80mm (in diameter)

Material: charcoal, coal

Capacity:1-30 t/h

Power:11-480 kw

Feeding Size:0-350 mm

Output Size: ≤35mm

Capacity:22-40 t/h

Power:22-45 kw

Speed of main shaft: 60r/min

Length: 3-6m

Capacity:6-16 t/h

Power:7.5-11 kw

Belt width:1.9m

Effective drying length: 20-40m

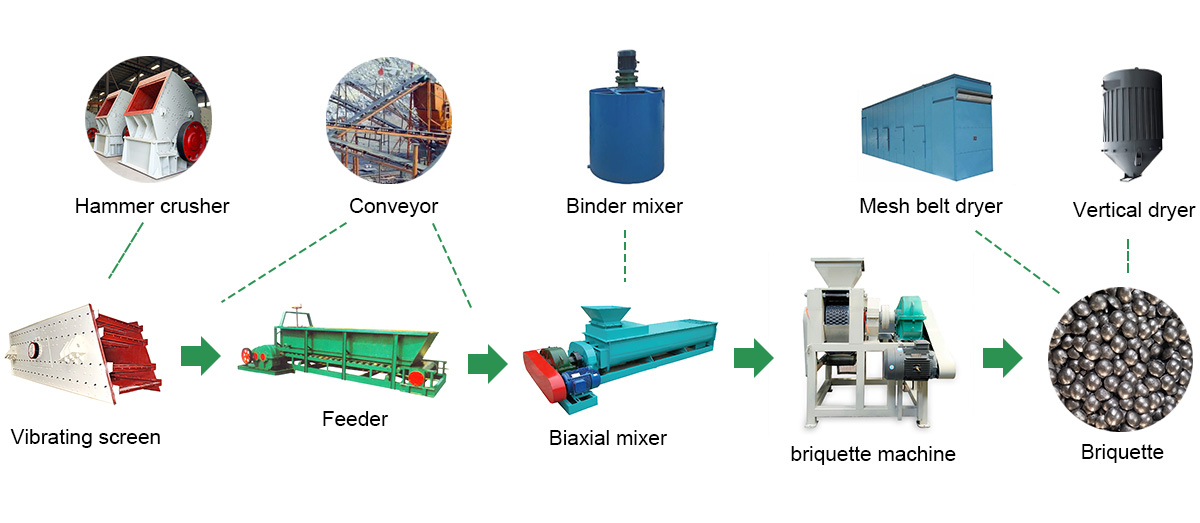

Ball press production line, with high automation, energy saving, and wide range of applications.

It is an essential equipment for material pressing. The production line mainly includes: vibrating screen, grinder, batching machine, dryer, mixer, ball press, feeder and conveyor.

It can press all kinds of iron powder, mineral powder, iron oxide scale, steel slag, coal, charcoal, refractory materials, etc. All materials that need to be smelted with powdery materials need ball press production line equipment.

The user can appropriately change the speed of the pre-press according to the pressing situation to achieve a higher pressing rate or greater production capacity. The compressed material is passed through the screening machine and the qualified briquettes are screened for packaging. The unscreened material can be returned to the warehouse and mix with the raw materials and then compacted.

| Model | Roller Diameter (mm) | Capacity (t/h) | Power (kw) | Reducer |

| SY-290 | 290 | 1-2.5 | 5.5-7.5 | 350 |

| SY-360 | 360 | 3-5 | 7.5-11 | 350 |

| SY-430 | 430 | 5-8 | 15 | 500 |

| SY-500 | 500 | 8-11 | 30 | 650 |

| SY-650 | 650 | 10-15 | 37-45 | 750 |

| SY-750 | 750 | 20-25 | 45 | 750 |

| SY-850 | 850 | 20-28 | 55 | 850 |

| SY-1000 | 1000 | 23-35 | 90 | 1000 |

NOTE:

1. The above machine are our standard specification, for turnkey project, or for different raw materials machine solutions, please contact us about your raw materials;

2. The machine voltage can be customized.