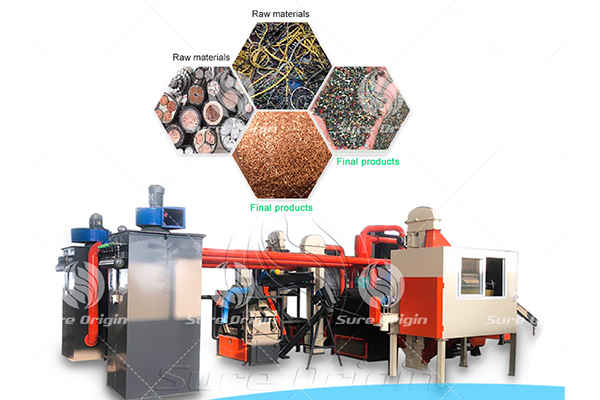

The so-called dry copper pelletizing machine refers to the machine that does not add water in the processing process. This type of waste copper granulator mainly adopts air sorter, or air vibrator or electrostatic separation and other more environmentally friendly sorting methods. The main process is: crushing - air separation - (electrostatic separation) - dust removal. (Electrostatic separation is rarely used in today's coppers.)

Wet scrap copper granulator

Wet scrap copper granulator is a more traditional way. The main idea of this separation method comes from beneficiation. Wet copper granulator is mainly separated by gravity vibrating screen. The main process is: crushing and (water) - gravity vibrating screen (add water), because in the production process to water so the overall environmental impact is small secondary pollution, but can effectively recover mixed wire, plug line and wool yarn, etc., very wide use.

Combined dry waste copper granulator

Application scope and function: after copper wire scrap copper wire cutting machine is specially used for processing automobile line, communication line and other lines with Φ20mm below and not suitable for all kinds of mixed wire processing stripping machine, crushing processing, vibrating screen separation, vibration separation, and water separation. Copper and plastic can be completely separated, to achieve the purpose of comprehensive utilization, high economic benefits. And no dust, no secondary pollution. In addition, the equipment is an integral modular structure, convenient installation and debugging, convenient transportation, power can be purchased after customer production, stable performance.

English

English