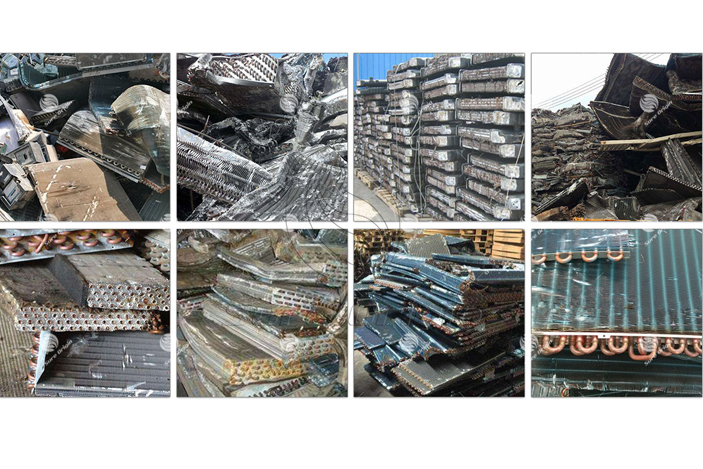

The heat sink used is basically composed of copper tubes, with a copper content of about 80%, aluminum for 15%, and iron for about 5%. Metal resources are relatively high-quality; the general water tank heat sink is also the heat sink in the air conditioner that we often use in our lives. The copper content is about 55%, the aluminum content is about 40%, and the iron content is about 5%. The content is relatively average. How to separate and recycle copper and aluminum in used air conditioner radiators?

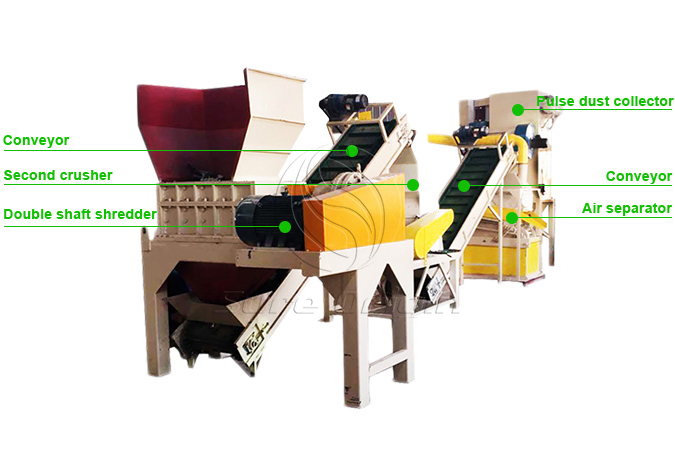

The crusher crushes the copper-aluminum water tank and the radiator to achieve an ideal recycling effect. This mechanical equipment is a customized crusher specially designed for processing copper and aluminum water tank radiators according to the characteristics of copper and aluminum. The recovery rate of copper, aluminum, iron and other metals can reach more than 99%. The back can be equipped with vibrating screens and The sorting device sorts according to the physical properties of copper and aluminum, and transports pure recycled copper and aluminum through multiple conveyors.

The waste radiator is manually put into a crusher. The crusher adopts a double-shaft pair-roller crusher to squeeze and tear the radiator into a strip radiator with a width of 5CM and uneven length. The material is conveyed to the second crusher by the first-breaking discharge conveyor. The second-breaking machine adopts a heavy-duty hammer crusher to crush the radiator into flakes, and then passes through the belt magnetic separator on the second-breaking discharge conveyor. Next, the iron in the material is separated by a magnetic separator, and the remaining copper and aluminum conveyors are air-separated in the air separator.

The sorting machine has 2 outlets, the No. 1 port is for heavier mixed materials (copper and a small amount of aluminum), and the No. 2 port is for lighter pure aluminum. The materials at Port 1 are then conveyed by the conveyor to the specific gravity separator for fine sorting, and the remaining copper and aluminum are sorted out. The dust collected in the first crusher, the second crusher, the magnetic separator, and the conveyor is collected by the high-pressure fan under negative pressure to the pulse dust collector, and there is a dust outlet under the pulse dust collector, and it is discharged to the storage by the screw conveyor frame.

If you have a friend who needs this machine, you can contact us at any time, thank you

English

English